Moulding machine MULTIFLEX for a better quality of your castings

Available in 3 versions with 4 possible squeeze heads, the moulding machine Multiflex combines both in wholly automated manual plant. Changing technology for the best quality of your casting parts.

Multiflex moulding machine advantages:

- Rigid and dense mould

- Better casting surface finish

- Dimensional stability

- Noise«less» operation

- Air«less» process – no compressed air

- No sand leakage (as in impulse/shoot)

- Pattern squeezes into mould ensures:

• High pattern surface hardness

• High mould hardness on box border - Multi-pistons ensures Deep Cavity and Self Core Hard mould

- Flexible and Modular machine – can be used for stand alone semi/fully automatic opération

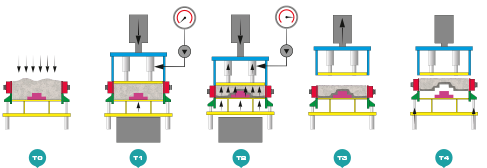

Moulding sequences of Multiflex moulding machine

- T0 : Pre-weighed sand falls inside box on pattern

- T1 : Squeeze head frame presses box pushing the pattern into sand from pattern surface upwards

- T2 : Squeeze head pressure gives control on mould hardness

- T3 : Squeeze head lift

- T4 : Mould stripping done on four guided hydraulic cylinders by stripper frame

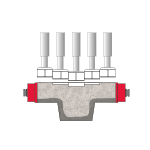

Squeeze head solutions

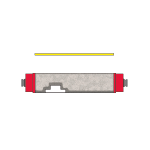

Simple

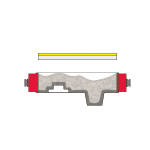

Simple with silicon

With special form

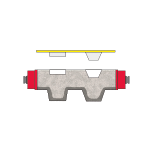

With multi-piston head

The moulding machine Multiflex in video

Some views of the molding machine

Our products

Characteristics of the 3 sizes of moulding machine Multiflex

| M1 | M2 | M3 | |

|---|---|---|---|

| Inside boxes size (mm) | from 400 x 400 to 600 x 500 | from 650 x 550 to 900 x 700 | from 1000 x 800 to 1300 x 1100 |

| Box height range (mm) | 75 to 300 | 150 to 350 | 200 to 450 |

| Moulding rate cadence (moules/h) | 60 to 120 | 50 to 100 | 40 to 80 |

| Specific squeeze pressure (adjustable) kg/cm2 | 10 | 10 | 10 |

| Overall dimensions (LxPxH) | 2,8 x 2 x 3 m | 3,2 x 2,4 x 3,5 m | 3,7 x 2,7 x 4 m |

| Electrical connected load (kW) | 9 à 11 | 15 à 27 | 30 à 50 |