Industrial robot, an asset for your productivity and your competitiveness

Confirmed supplier in industrial automation, Scoval Robotic designs and integrates robotics into your manufacturing process with efficiency and reliability by using virtual reality to visualize your project before implementation.

In all industrial areas, the high-performance robots and Scoval Robotic expertise will allow you to meet the challenge of the Industry of the future.

Dans tous les domaines industriels, les hautes performances des robots et l’expertise Scoval Robotic vous permettront de relever le défi de l’Industrie du futur.

Integrating a robot : what are the advantages?

- Reproducibility and reliability of operations guaranteed

- Improved productivity and quality level

- Depreciation of the installation

- Reassignment of operators to more technical tasks

- Easy integration and evolution in a process

- Manufacturing

- Connectability and maintainability

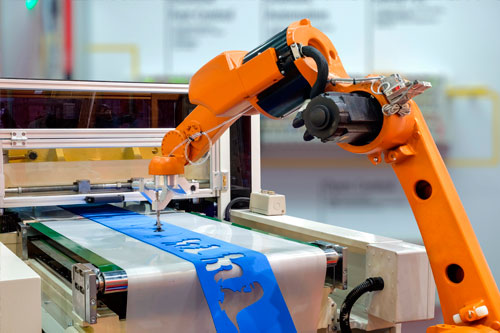

Integrating an industrial robot: for what use? :

- Control

- Stick

- Coat

- Deburr

- Transfer

- Machine

- View

- Punch

- Engrave

- Handle

- Unpack

- Assemble

- Clean

- …

Robotization in your industrial project: the Scoval service

Support upstream of the project in establishing your specifications according to your needs and environment

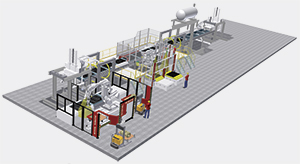

- 3D pre-study and virtual reality

- Study, definition, manufacture of equipment and associated structures

- Load handled from 0 to 2000 kg

- All brands of robots

- 4 to 6 axis technology

- Type of work: all industries

- In stand-alone or integrated operation

- Installation, start and after-sales service

A concrete example:

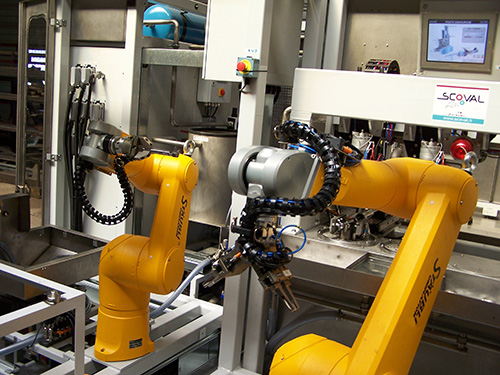

Robotization of an existing molding line, boxes dimensions 1600 x 1400 x 400 mm.

Cleaning robotization of tapping hole and risers.

Installation characteristics

Installation of 5 robots to ensure:

- Fin milling on box.

- Cores laying online, weight 250kg max with 2D vision.

- Filters laying and marking of the interior mould.

- Blow-cleaning risers-holes on cope box.

- Big cores laying out of line, weight 600kg max with 3D vision.

Each robot adapts its cycle according to the production information transmitted by the existing PLC machine of the moulding line.

Customer benefits

- Reproducibility and reliability of the operation guaranteed

- Improved productivity and quality level

- Very fast amortization of the installation

- Reassignment of the operator to more technical and less hard work

Support upstream of the project in establishing your specifications according to your needs and environment

Support upstream of the project in establishing your specifications according to your needs and environment